E kākau inoa i kā mākou pāpili kaiapili no ka pou wikiwiki

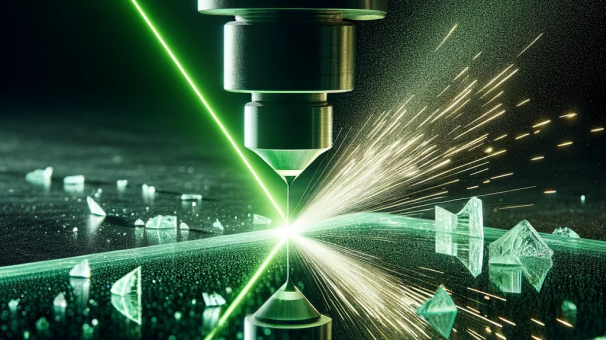

Hoʻolauna i ka Hana ʻana o ka Laser ma ka Hana ʻana

Ua ʻike ʻia ka ʻenehana hana laser i ka ulu wikiwiki a ua hoʻohana nui ʻia ma nā ʻano like ʻole, e like me ka aerospace, automotive, electronics, a me nā mea hou aku. He kuleana koʻikoʻi kona i ka hoʻomaikaʻi ʻana i ka maikaʻi o ka huahana, ka huahua hana, a me ka automation, me ka hoʻemi ʻana i ka haumia a me ka hoʻohana ʻana i nā mea (Gong, 2012).

Ka Hana ʻana i ka Laser ma nā Mea Metala a me nā Mea ʻAʻole Metala

ʻO ka hoʻohana nui ʻana o ka hana laser i nā makahiki he ʻumi i hala iho nei, ʻo ia nā mea metala, me ka ʻoki ʻana, ka hoʻoheheʻe ʻana, a me ke kāpili ʻana. Eia nō naʻe, ke hoʻonui nei ke kahua i nā mea ʻaʻole metala e like me nā lole, ke aniani, nā plastics, nā polymers, a me nā keramika. Hoʻopuka kēlā me kēia o kēia mau mea i nā manawa kūpono i nā ʻoihana like ʻole, ʻoiai ua loaʻa iā lākou nā ʻano hana hana i hoʻokumu ʻia (Yumoto et al., 2017).

Nā Pilikia a me nā Hana Hou i ka Hana ʻana i ke Aniani me ka Laser

ʻO ke aniani, me kāna mau noi ākea i nā ʻoihana e like me ke kaʻa, ke kūkulu ʻana, a me nā mea uila, he wahi koʻikoʻi ia no ka hana ʻana i ka laser. ʻO nā ʻano ʻoki aniani kuʻuna, e pili ana i ka hui paʻakikī a i ʻole nā mea hana daimana, ua kaupalena ʻia e ka haʻahaʻa haʻahaʻa a me nā ʻaoʻao ʻino. I ka hoʻohālikelike ʻana, hāʻawi ka ʻoki laser i kahi koho ʻē aʻe ʻoi aku ka maikaʻi a me ka pololei. He mea maopopo loa kēia i nā ʻoihana e like me ka hana ʻana i nā kelepona akamai, kahi e hoʻohana ʻia ai ka ʻoki laser no nā uhi lens kāmela a me nā pale hōʻike nui (Ding et al., 2019).

Ka Hana ʻana i ka Laser o nā ʻAno Aniani Waiwai Kiʻekiʻe

ʻO nā ʻano aniani like ʻole, e like me ke aniani optical, ke aniani quartz, a me ke aniani sapphire, he mau pilikia kūikawā ma muli o ko lākou ʻano palupalu. Eia nō naʻe, ua hiki i nā ʻenehana laser holomua e like me ke kālai laser femtosecond ke hana pololei i kēia mau mea (Sun & Flores, 2010).

Ka Hopena o ka Nalu ma nā Kaʻina Hana ʻenehana Laser

Hoʻopilikia nui ka nalu o ka laser i ke kaʻina hana, ʻoi aku hoʻi no nā mea e like me ke kila kūkulu. Ua kālailai ʻia nā lasers e hoʻopuka ana i nā wahi ultraviolet, ʻike ʻia, kokoke a mamao o ka infrared no ko lākou mana koʻikoʻi no ka hoʻoheheʻe ʻana a me ka mahu (Lazov, Angelov, & Teirumnieks, 2019).

Nā noi like ʻole e pili ana i nā nalu

ʻAʻole koho wale ʻia ke koho ʻana o ka nalu laser akā hilinaʻi nui ia i nā waiwai o ka mea a me ka hopena i makemake ʻia. No ka laʻana, ʻoi aku ka maikaʻi o nā lasers UV (me nā nalu pōkole) no ke kahakaha pololei a me ka micromachining, no ka mea hiki iā lākou ke hana i nā kikoʻī maikaʻi aʻe. ʻO kēia ka mea kūpono iā lākou no nā ʻoihana semiconductor a me microelectronics. I ka hoʻohālikelike ʻana, ʻoi aku ka maikaʻi o nā lasers infrared no ka hana ʻana i nā mea mānoanoa ma muli o ko lākou hiki ke komo hohonu, e kūpono ai lākou no nā noi ʻoihana kaumaha. (Majumdar & Manna, 2013). Pēlā nō, ʻo nā lasers ʻōmaʻomaʻo, e hana pinepine ana ma kahi nalu o 532 nm, loaʻa i ko lākou niche i nā noi e koi ana i ka pololei kiʻekiʻe me ka hopena wela liʻiliʻi. He kūpono loa lākou i ka microelectronics no nā hana e like me ke ʻano circuit, i nā noi lapaʻau no nā kaʻina hana e like me ka photocoagulation, a ma ka ʻāpana ikehu hou no ka hana ʻana o nā cell solar. ʻO ka nalu kū hoʻokahi o nā lasers ʻōmaʻomaʻo e kūpono iā lākou no ka hōʻailona a me ke kahakaha ʻana i nā mea like ʻole, me nā plastics a me nā metala, kahi e makemake ʻia ai ke ʻano kiʻekiʻe a me ka pōʻino liʻiliʻi o ka ʻili. Hōʻike kēia hoʻololi o nā lasers ʻōmaʻomaʻo i ke koʻikoʻi o ke koho ʻana i ka nalu i ka ʻenehana laser, e hōʻoiaʻiʻo ana i nā hopena maikaʻi loa no nā mea kikoʻī a me nā noi.

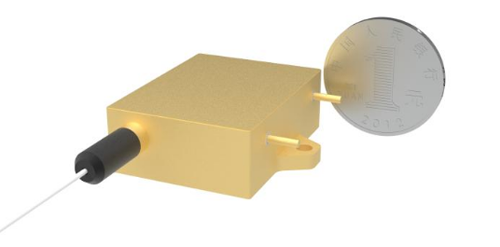

ʻO kaKukuna ʻōmaʻomaʻo 525nmhe ʻano kikoʻī o ka ʻenehana laser i hōʻike ʻia e kāna hoʻokuʻu kukui ʻōmaʻomaʻo ʻokoʻa ma ka nalu o 525 nanometers. Loaʻa i nā lasers ʻōmaʻomaʻo ma kēia nalu ka hoʻohana ʻana i ka photocoagulation retinal, kahi e pono ai ko lākou mana kiʻekiʻe a me ka pololei. He mea pono nō hoʻi lākou i ka hana ʻana i nā mea, ʻoi aku hoʻi i nā kahua e pono ai ka hana ʻana i ka hopena wela pololei a me ka liʻiliʻi..ʻO ka hoʻomohala ʻana o nā diode laser ʻōmaʻomaʻo ma ka substrate c-plane GaN i nā nalu lōʻihi ma 524-532 nm e hōʻailona ana i kahi holomua koʻikoʻi i ka ʻenehana laser. He mea koʻikoʻi kēia hoʻomohala ʻana no nā noi e koi ana i nā ʻano nalu kikoʻī.

Nā Kumu Nalu Hoʻomau a me nā Kumu Laser i Hoʻohālike ʻia

ʻO nā kumu laser hoʻomau (CW) a me nā kumu laser quasi-CW i hoʻohālikelike ʻia ma nā nalu like ʻole e like me ka infrared kokoke (NIR) ma 1064 nm, ʻōmaʻomaʻo ma 532 nm, a me ka ultraviolet (UV) ma 355 nm e noʻonoʻo ʻia no ka hoʻopili ʻana o ka laser i nā cell solar emitter koho. Loaʻa nā hopena o nā nalu like ʻole no ka hana ʻana i ka hoʻololi a me ka pono (Patel et al., 2011).

Nā Lasers Excimer no nā Mea Wide Band Gap

ʻO nā lasers Excimer, e hana ana ma kahi nalu UV, he kūpono ia no ka hana ʻana i nā mea ākea-bandgap e like me ke aniani a me ka polymer carbon-reinforced fiber (CFRP), e hāʻawi ana i ka pololei kiʻekiʻe a me ka hopena wela liʻiliʻi (Kobayashi et al., 2017).

Nā Lasers Nd:YAG no nā noi ʻoihana

ʻO nā lasers Nd:YAG, me ko lākou hiki ke hoʻololi i ke ʻano o ka hoʻonohonoho ʻana i ka nalu, hoʻohana ʻia i nā ʻano hana like ʻole. ʻO ko lākou hiki ke hana ma 1064 nm a me 532 nm e ʻae i ka maʻalahi i ka hana ʻana i nā mea like ʻole. No ka laʻana, ʻo ka nalu 1064 nm he kūpono no ke kahakaha hohonu ʻana ma nā metala, ʻoiai ʻo ka nalu 532 nm e hāʻawi i ke kahakaha ʻana i ka ʻili kiʻekiʻe ma nā plastics a me nā metala i uhi ʻia. (Moon et al., 1999).

→Nā Huahana Pili:ʻO ka laser paʻa-mokuʻāina CW Diode-pumped me ka nalu 1064nm

Kuʻihao Laser Fiber Mana Kiʻekiʻe

Hoʻohana ʻia nā lasers me nā nalu kokoke i 1000 nm, nona ke ʻano kukuna maikaʻi a me ka mana kiʻekiʻe, i ka hoʻopili ʻana i ka laser keyhole no nā metala. Hoʻoheheʻe pono kēia mau lasers i nā mea, e hana ana i nā hoʻopili kiʻekiʻe (Salminen, Piili, & Purtonen, 2010).

Hoʻohui ʻana o ka Hana ʻana o ka Laser me nā ʻenehana ʻē aʻe

ʻO ka hoʻohui ʻana o ka hana laser me nā ʻenehana hana ʻē aʻe, e like me ke kāpili ʻana a me ka wili ʻana, ua alakaʻi i nā ʻōnaehana hana ʻoi aku ka maikaʻi a me ka maʻalahi. He mea pono loa kēia hoʻohui ʻana i nā ʻoihana e like me ka hana ʻana i nā mea hana a me nā make a me ka hoʻoponopono ʻenekini (Nowotny et al., 2010).

Ka Hana ʻana i ka Laser ma nā kahua e kū mai ana

Hoʻonui ka hoʻohana ʻana o ka ʻenehana laser i nā kahua e kū mai ana e like me ka semiconductor, ka hōʻike, a me nā ʻoihana kiʻiʻoniʻoni lahilahi, e hāʻawi ana i nā hiki hou a me ka hoʻomaikaʻi ʻana i nā waiwai o nā mea, ka pololei o ka huahana, a me ka hana o nā hāmeʻa (Hwang et al., 2022).

Nā ʻAno Hou i ka Hana ʻana i ka Laser

ʻO nā hoʻomohala e hiki mai ana i ka ʻenehana hana laser e kālele ana i nā ʻenehana hana hou, ka hoʻomaikaʻi ʻana i nā ʻano huahana, ka ʻenekinia ʻana i nā ʻāpana multi-material i hoʻohui ʻia a me ka hoʻonui ʻana i nā pono waiwai a me nā kaʻina hana. Hoʻokomo pū kēia me ka hana wikiwiki laser o nā hale me ka porosity i kāohi ʻia, ka hoʻopili ʻana i ka hybrid, a me ka ʻoki ʻana i ka profile laser o nā pepa metala (Kukreja et al., 2013).

ʻO ka ʻenehana hana laser, me kāna mau noi like ʻole a me nā hana hou e hoʻomau nei, ke hoʻohālikelike nei i ka wā e hiki mai ana o ka hana ʻana a me ka hana ʻana i nā mea. ʻO kona versatility a me ka pololei e lilo ia i mea hana pono ʻole i nā ʻoihana like ʻole, e hoʻokuke ana i nā palena o nā ʻano hana hana kuʻuna.

ʻO Lazov, L., Angelov, N., & Teirumnieks, E. (2019). KE ʻANO NO KA HOʻOLOILOI MUA ʻANA O KA DENSITY MANA KOʻIKOʻI I NĀ KAʻINA ʻENEHANA LASER.KAIAO. NĀ ʻENEHANA. NĀ KUMUWAIWAI. Nā Hana o ka ʻAha Kūkākūkā ʻEpekema a me nā Hana Kūpono o ka Honua. Loulou

ʻO Patel, R., Wenham, S., Tjahjono, B., Hallam, B., Sugianto, A., & Bovatsek, J. (2011). Hana wikiwiki ʻana o nā pūnaewele solar Selective Emitter Doping Laser me ka hoʻohana ʻana i ka 532nm Continuous Wave (CW) a me nā kumu laser Quasi-CW i hoʻohālikelike ʻia.Loulou

Kobayashi, M., Kakizaki, K., Oizumi, H., Mimura, T., Fujimoto, J., & Mizoguchi, H. (2017). DUV mana kiʻekiʻe lasers kaʻina hana no ke aniani a me CFRP.Loulou

Moon, H., Yi, J., Rhee, Y., Cha, B., Lee, J., & Kim, K.-S. (1999). ʻO ka hoʻonui pinepine ʻana o ka intracavity mai kahi laser Nd:YAG i hoʻopili ʻia me ka diffusive reflector-type diode me ka hoʻohana ʻana i kahi kristal KTP.Loulou

Salminen, A., Piili, H., & Purtonen, T. (2010). ʻO nā hiʻohiʻona o ka welding laser fiber mana kiʻekiʻe.Nā Hana o ka ʻAhahui o nā ʻEnekinia Mekanika, Māhele C: Journal of Mechanical Engineering Science, 224, 1019-1029.Loulou

Majumdar, J., & Manna, I. (2013). Hoʻolauna i ka hana ʻana i nā mea i kōkua ʻia e ka laser.Loulou

Gong, S. (2012). Nā noiʻi a me nā noiʻi o ka ʻenehana hana laser holomua.Loulou

ʻO Yumoto, J., Torizuka, K., & Kuroda, R. (2017). Ka Hoʻomohala ʻana i kahi Moena Hoʻāʻo Hana Laser a me ka ʻIkepili no ka Hana ʻana i nā Mea Laser.Ka Loiloi o ka ʻenekinia Laser, 45, 565-570.Loulou

Ding, Y., Xue, Y., Pang, J., Yang, L.-j., & Hong, M. (2019). ʻO nā holomua i ka ʻenehana nānā i loko o kahi no ka hana laser.SCIENTIA SINICA Physica, Mechanica & Astronomica. Loulou

Sun, H., & Flores, K. (2010). Ka Nānā ʻana i ka Microstructural o kahi aniani metala nui i hana ʻia me ka laser Zr.Nā Hana Metallurgical a me nā Mea Hana A. Loulou

Nowotny, S., Muenster, R., Scharek, S., & Beyer, E. (2010). Kelepona laser i hoʻohui ʻia no ka hoʻopili laser i hui pū ʻia a me ka wili ʻana.ʻAhahui Hana Hoʻonohonoho, 30(1), 36-38.Loulou

ʻO Kukreja, LM, Kaul, R., Paul, C., Ganesh, P., & Rao, BT (2013). Nā ʻenehana hana mea laser e kū mai ana no nā noi ʻoihana e hiki mai ana.Loulou

ʻO Hwang, E., Choi, J., & Hong, S. (2022). Nā kaʻina hana vacuum i kōkua ʻia e ka laser no ka hana ʻana me ka pololei loa, me ka hua kiʻekiʻe.Nanoscale. Loulou

Ka manawa hoʻouna: Ian-18-2024